At its core, the transverse rigidity test is a standardized laboratory procedure that measures a motorcycle boot's resistance to being crushed. It is designed to simulate the immense force your foot could be subjected to if a motorcycle falls on it, assessing the structural integrity of the boot's sole and its ability to protect the delicate bones within.

The real purpose of this test isn't just to generate a number; it's to quantify a boot's ability to prevent a common and severe motorcycle injury. Understanding this single test is the first step to decoding the overall safety rating of your gear.

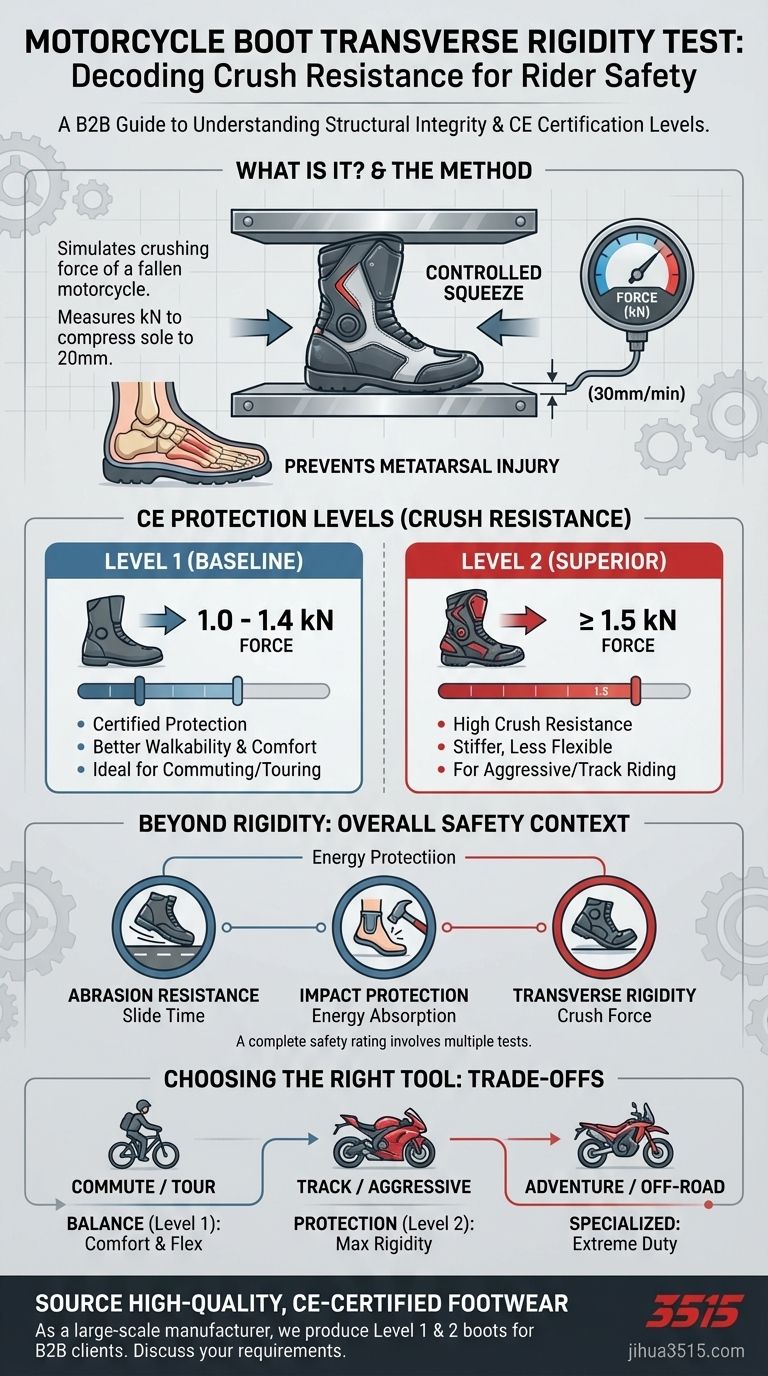

What is Transverse Rigidity?

The Purpose: Preventing Crushing Injuries

The term "transverse rigidity" refers to the stiffness of the boot across its width. The test's primary goal is to ensure the boot can withstand the crushing force of a bike's weight pinning the rider's foot to the ground.

Without adequate rigidity, the sole could deform or collapse, transferring the full force of the impact directly to the metatarsal bones of the foot.

The Method: A Controlled Squeeze

During the test, a boot is placed between two plates that compress it across the sole at a controlled speed of 30mm per minute.

The machine measures the amount of force (in kilonewtons, or kN) required to compress the sole to a specific width, typically 20mm. A higher force value indicates a more rigid and protective boot.

The Ratings: Level 1 vs. Level 2

The results of this test are categorized into two distinct protection levels, which are part of the overall CE safety rating.

- Level 1: The boot must withstand between 1.0 kN and 1.4 kN of force before being crushed. This offers a certified baseline of protection.

- Level 2: The boot must withstand at least 1.5 kN of force. This represents a significantly higher level of crush resistance for more demanding riding situations.

Where Rigidity Fits into Overall Boot Safety

Transverse rigidity is a critical test, but it is only one piece of the puzzle. A truly protective boot is evaluated against a range of potential accident scenarios.

Abrasion Resistance

This test measures how long the boot's materials can withstand being scraped against a rough surface, simulating a slide on pavement. The boot is divided into two key zones.

- Area A: High-impact zones like the sole, front, and back.

- Area B: All other parts of the boot.

Level 2 certification requires the materials in these zones to last significantly longer under abrasion than Level 1 materials.

Impact Resistance

Other critical tests measure the boot's ability to absorb and dissipate energy from a direct impact, particularly around the ankle and shin areas. This is where features like reinforced ankle cups and shin plates are evaluated.

Understanding the Trade-offs

Choosing the right boot involves balancing maximum protection with practical usability.

Protection vs. Comfort

A boot with extremely high transverse rigidity (Level 2) will be very stiff. While this is excellent for protection against crushing, it can make walking and feeling the controls more difficult.

The "Walkability" Factor

Less rigid boots (Level 1) often provide more flexibility in the sole, making them more comfortable for walking around off the bike. This can be a major consideration for commuters or tourists.

Cost and Materials

Achieving Level 2 ratings, especially for rigidity, often requires more advanced materials and complex construction techniques. This typically results in a higher price point compared to Level 1 certified boots.

Making the Right Choice for Your Goal

- If your primary focus is track days or aggressive street riding: Prioritize a boot with a Level 2 rating for transverse rigidity to ensure the highest level of crush protection.

- If your primary focus is daily commuting or casual touring: A Level 1 boot offers certified protection while providing a better balance of comfort, flexibility, and affordability.

- If your primary focus is adventure or off-road riding: Seek out boots specifically designed for this purpose, which often feature extreme rigidity and specialized impact armor for unique hazards.

Ultimately, understanding these safety metrics empowers you to choose the right tool for the job.

Summary Table:

| Protection Level | Required Force (kN) | Key Purpose |

|---|---|---|

| Level 1 | 1.0 - 1.4 kN | Certified baseline protection, better comfort and walkability. |

| Level 2 | ≥ 1.5 kN | Superior crush resistance for aggressive riding and track use. |

Ready to source high-quality, safety-certified motorcycle boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of CE-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of motorcycle boots, engineered to meet Level 1 and Level 2 transverse rigidity standards for optimal rider protection.

Contact us today to discuss your specific requirements and leverage our manufacturing expertise.

ビジュアルガイド

関連製品

- 安全靴卸売メーカー カスタム OEM ・ ODM 生産

- プレミアム卸売防水安全ブーツ 産業市場向け高性能保護

- プレミアム難燃性防水安全ブーツ・靴

- 高性能難燃防水安全ブーツ

- バルク供給向けプレミアムグレインレザー安全ブーツ

よくある質問

- 安全靴におけるフロント硬化材の役割とは?建設・溶接作業における必須保護機能

- ぬかるんだ、または浸水した建設現場でハイカットの安全靴を使用する利点は何ですか?困難な状況下での安全と健康を確保する

- 安全性のある履物における防水性と透湿性はなぜ重要なのでしょうか? 作業者の健康と安全のために不可欠

- 油に強い安全ブーツはどのような場所で使用すべきか? 油っぽく危険な職場のための必須保護具

- コンクリート業界の労働安全衛生管理システム(SMK3)におけるリスク管理において、工業用安全靴はどのような役割を果たしますか?安全とコンプライアンスを向上させる

- 安全靴のASTM F2412規格とは何ですか?保護靴規格の究極ガイド

- AMEDAはフットウェアの研究開発にどのように活用されますか?足首の安定性を向上させるための安全靴とトレーニングブーツの最適化

- 安全靴に定期的に行うべきメンテナンスチェックは何ですか? A 毎日の安全チェックリスト